Downtime is one of the most critical threats to fleets today. It can have a major impact on operational costs and can have a negative effect on fleet companies’ return on investment. We use downtime as one of the many examples to explain predictive maintenance.

Predictive maintenance can also have a positive effect on the number of road incidents. Because defects can be detected earlier, the number of vehicles on the road with potential risks will decrease.

Three key areas of maintenance

We can divide maintenance into three key areas where Squarell’s vehicle data can predict necessary maintenance:

- Planned maintenance ⇒ take early action

- Predictive maintenance ⇒ continuous monitoring

- Reactive maintenance ⇒ utilize dashboard lights

1. Planned maintenance: take early action

Planned maintenance is often recommended by the vehicle’s manufacturer. A message on the dashboard informs the driver about the upcoming service call and gives him the responsibility to follow-up on it.

The Squarell solution

With Squarell’s data, you can take early action and take the upcoming service into account when scheduling maintenance. The data that Squarell provides covers not only maintenance intervals and mileage, but also engine hours and even the total number of engine revolutions.

Example parameters

- Service interval

- Total vehicle distance

- Total engine hours

- Total engine revolutions

2. Predictive maintenance: continuous monitoring

Since the checks performed during scheduled maintenance are snapshots, parts may still break down over time. A technician can make an estimate based on wear and tear when maintenance should take place, but is not able to predict technical failures.

The Squarell solution

With Squarell’s data, it is possible to extend the snapshot intervals to continuous monitoring and prevent future failures. For example: when the brake wear on one side of the vehicle increases, it usually indicates a stuck brake caliper. Another example: if the temperature in a tire becomes too high, there is a high risk of a blowout.

Examples parameters

- Brake lining remaining

- Tyre pressure/temperature

- Battery potential

- Engine coolant temperature

- Engine oil temperature

- Transmission oil temperature

3. Reactive maintenance: utilise dashboard lights

Reactive maintenance is indicated when the previous categories have not been able to prevent a definitive failure.

The Squarell solution

Dashboard lighting informs the driver about electrical faults or defective parts. Squarell has the solution to make these lights available to the fleet manager so that he can react directly to this malfunction. He can arrange parts in advance, reserve time in the workshop and possibly deploy a replacement vehicle.

Error codes for remote diagnosis

The Squarell data can be extended in specific cases with the underlying error codes. If the fleet owner is able to interpret these codes, he will be able to plan even more accurately using remote diagnosis.

Please note that interpreting these codes is a specific task that can only be performed if the receiver has a database in which the codes are explained. Squarell can give the code, but not the corresponding error description. Moreover, this solution is very specific and the number of supported vehicles may be limited.

Examples parameters

- Engine MIL indicator

- Worn brake lining

- Brake failure

- ABS failure

- AdBlue level low

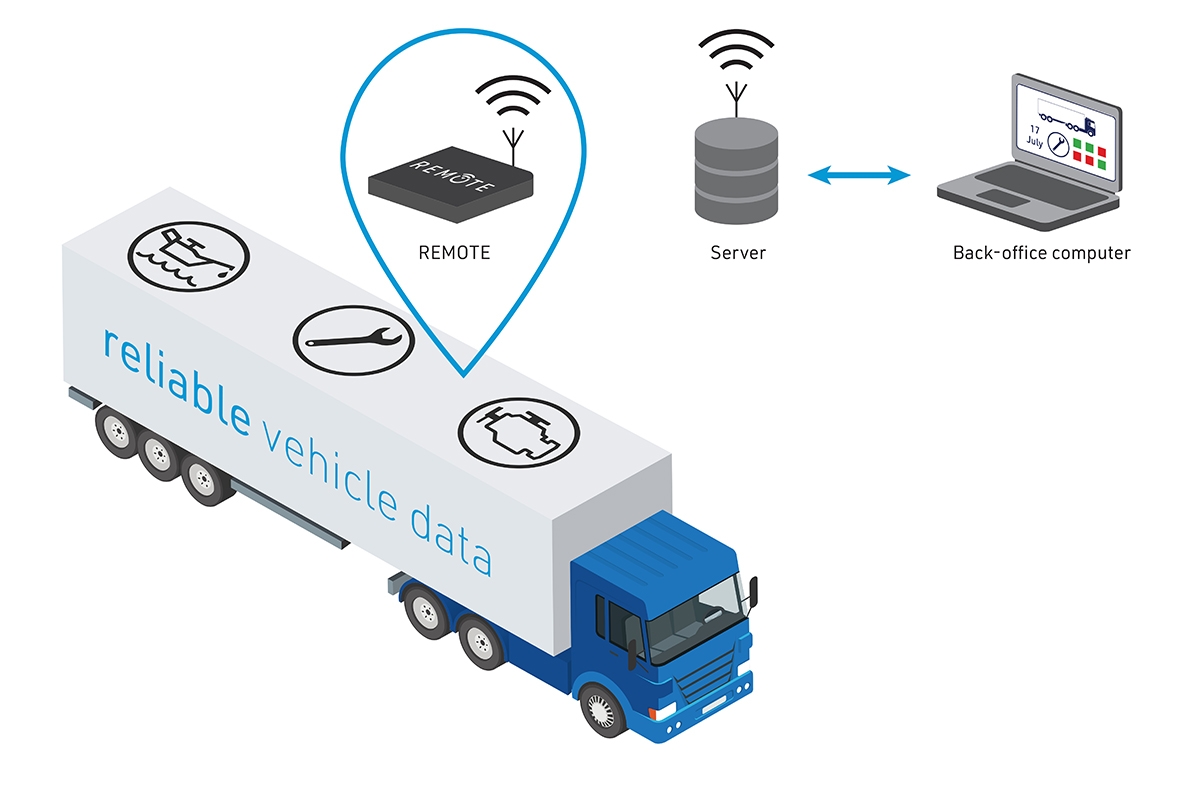

Technical infographic

The Squarell Vehicle Data Interface then processes and translates the data obtained and sends it via a modem to the server of the Telematics Service Provider (TSP). The TSP now receives a fault message, for example, and can decide to carry out maintenance on the vehicle.

Squarell hardware

Squarell’s solutions are brand-independent, ideal for comparing data from fleets with various vehicle brands. Access to the vehicle’s fleet management system is not required to be used for predictive maintenance. Squarell’s hardware is able to read vehicle data from any vehicle on the market without causing warranty and liability issues. Check the available data of all supported vehicles.

Request info about maintenance solutions

Contact our account manager for details and prices